AAAC Conductor are used as bare overhead conductors for primary & secondary distribution. Designed utilizing a high-strength aluminum alloy to achieve a high strength-to-weight ratio, affords better sag characteristics. Aluminum alloy gives AAAC Conductor-6201 higher resistance to corrosion than ACSR Conductor.

Kindly complete the part numbers for these cables by adding the suffix (in place of ‘xx’) for the colour required: 01 – green, 02 – black, 03 – red, 04 – blue, 05 – yellow, 06 – grey, 07 – white.

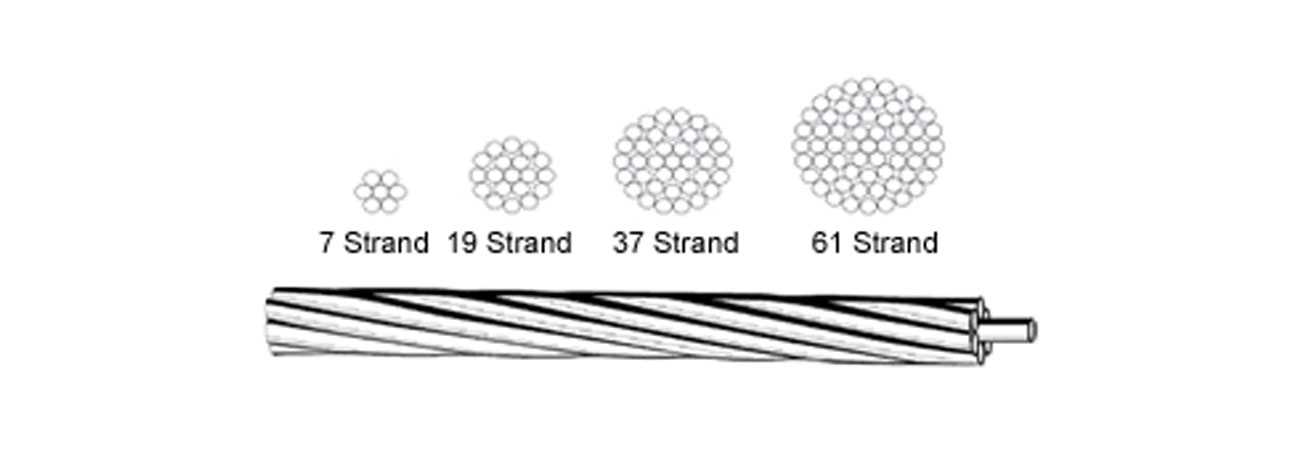

| Sl. No. | Nom. Al Area mm | Standing & wire Dia in mm | Approx. Overall Dia in mm | Approx. Mass in kg/km | Calculated Maximum Resistance at 20 C (Ohms/km) | Approx. Calculated Breaking Load (kN) |

| 1 | 15 | 3/2.5 | 5.39 | 40.15 | 2.3040 | 4.33 |

| 2 | 22 | 7/2.00 | 6.00 | 60.16 | 1.5410 | 6.45 |

| 3 | 34 | 7/2.50 | 7.50 | 94.00 | 0.9900 | 10.11 |

| 4 | 55 | 7/3.15 | 9.45 | 149.20 | 0.6210 | 16.30 |

| 5 | 80 | 7/3.81 | 11.43 | 218.26 | 0.4250 | 23.41 |

| 6 | 100 | 7/4.26 | 12.78 | 272.86 | 0.3390 | 29.26 |

| 7 | 125 | 19/2.89 | 14.45 | 342.51 | 0.2735 | 36.64 |

| 8 | 148 | 19/3.15 | 15.75 | 406.91 | 0.2298 | 43.50 |

| 9 | 173 | 19/3.40 | 17.00 | 474.02 | 0.1969 | 50.54 |

| 10 | 200 | 19/3.66 | 18.30 | 549.40 | 0.1710 | 58.66 |

| 11 | 232 | 19/3.94 | 19.70 | 636.67 | 0.1471 | 68.05 |

| 12 | 288 | 37/3.15 | 22.05 | 794.05 | 0.1182 | 84.71 |

| 13 | 346 | 37/3.45 | 24.15 | 952.56 | 0.0984 | 101.58 |

| 14 | 400 | 37/3.71 | 25.97 | 1101.63 | 0.0855 | 117.40 |

| 15 | 465 | 37/4.00 | 28.00 | 1280.50 | 0.0734 | 136.38 |

| 16 | 525 | 61/3.31 | 29.79 | 1448.39 | 0.0651 | 146.03 |

| 17 | 570 | 61/3.45 | 31.05 | 1573.71 | 0.0598 | 158.66 |

| 18 | 604 | 61/3.55 | 31.95 | 1666.00 | 0.0568 | 167.99 |

| 19 | 642 | 61.3.66 | 32.94 | 1771.36 | 0.0534 | 178.43 |

| 20 | 695 | 61/3.81 | 34.29 | 1919.13 | 0.0492 | 193.25 |

| 21 | 767 | 61/4.00 | 36.00 | 2115.54 | 0.0446 | 213.01 |

© 2017. All rights reserved Murti Udyog Ltd.

Developed & Maintained by Softron

Back To Top