AAC Conductor are used primarily for overhead transmission & also as primary and secondary distribution, where ampacity must be maintained and a lighter conductor (compared to ACSR Conductor) is desired, when conductor strength is not a critical factor.

| Code | Nominal Aluminium Area mm² | Stranding & Wire Diameter mm | Approx Over all Dia mm | Approx Mass Kg/Km | Calculated Resistance at 20 C Max / KM | Approx Calculated Breaking Load KN | Approx. Calculated Breaking Load (kN) |

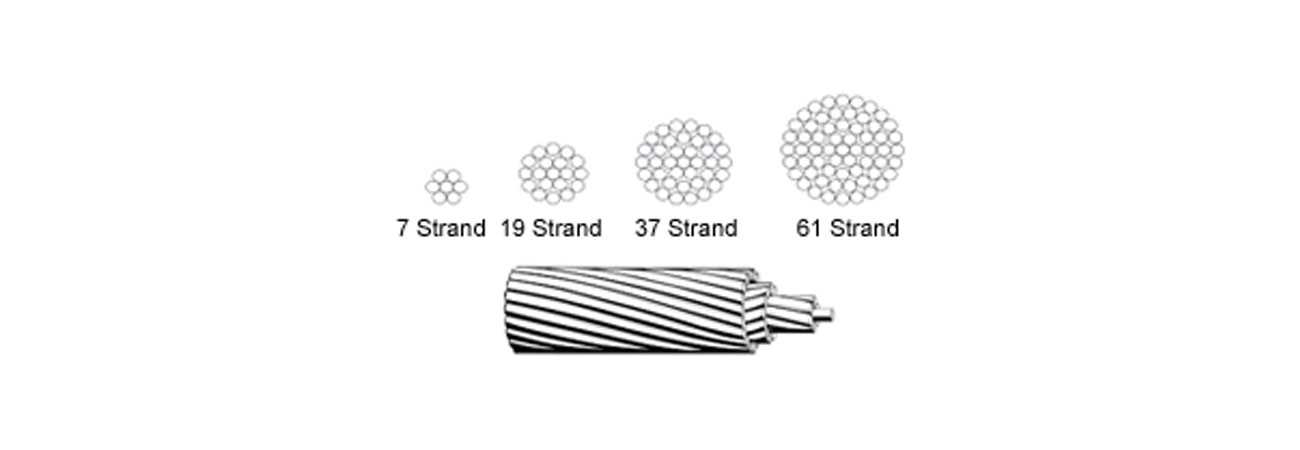

| Gnat | 25 | 7/2.21 | 6.63 | 74 | 1.093 | 4.52 | 4.52 |

| Ant | 50 | 7/3.10 | 9.30 | 145 | 0.556 | 8.25 | 8.25 |

| Wasp | 100 | 7/4.39 | 13.17 | 290 | 0.277 | 15.96 | 15.96 |

| Special | 150 | 19/3.18 | 15.90 | 415 | 0.915 | 23.28 | 23.28 |

| Spider | 240 | 19/3.99 | 19.95 | 654 | 0.1244 | 35.74 | 35.74 |

| Butterfly | 300 | 19/4.65 | 23.25 | 888 | 0.01971 | 48.74 | 48.74 |

© 2017. All rights reserved Murti Udyog Ltd.

Developed & Maintained by Softron

Back To Top